The Benefits of Investing in High-Quality Industrial Scales for Heavy Weighing

The Benefits of Investing in High-Quality Industrial Scales for Heavy Weighing

Blog Article

Why to Select Industrial Scales for Accurate Weight Measurement in Numerous Industries

In an age where accuracy is extremely important, the selection of industrial ranges for exact weight measurement plays an essential role across varied fields. These ranges not only enhance functional performance yet also guarantee conformity with governing criteria, impacting whatever from production to shipping.

Value of Accurate Weight Dimension

In the world of commercial operations, the importance of precise weight measurement can not be overstated. Exact weight dimension is fundamental throughout different markets, affecting both operational efficiency and product quality - Industrial Scales. It acts as an important consider supply monitoring, guaranteeing that products are appropriately accounted for, thus reducing waste and decreasing costs

In manufacturing, accurate weight dimension straight affects production processes. Anomalies in weight can bring about subpar products or excessive source appropriation, influencing total productivity. In addition, in sectors such as drugs and food manufacturing, adherence to stringent weight specifications is vital for governing conformity and consumer safety.

Moreover, accurate weight dimensions promote efficient logistics and supply chain management. Appropriately weighed deliveries ensure that transport costs are optimized and that inventory degrees are preserved precisely, thereby protecting against stock shortages or overstock circumstances.

Types of Industrial Scales

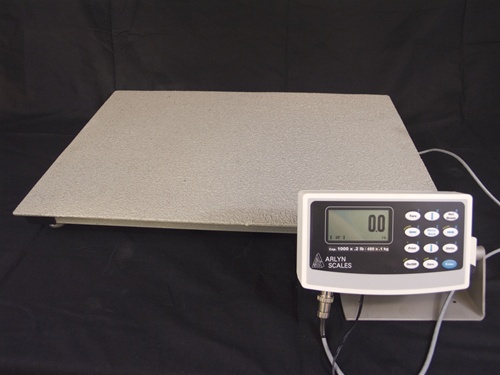

A wide range of industrial ranges are available, each developed to fulfill certain measurement requires throughout diverse industries. Usual types consist of flooring scales, which are robust and appropriate for considering big items or pallets in warehouses and warehouse. Bench scales are smaller and ideal for lighter materials, often utilized in retail setups or manufacturing for exact section control.

One more group is mobile scales, which use the adaptability to be moved easily around task websites, making them ideal for field procedures or short-lived setups. Precision ranges, on the various other hand, are developed for high precision and are regularly utilized in laboratories and high quality control settings.

Load cells are essential parts in numerous industrial scales, converting pressure right into an electric signal for exact readings. Furthermore, truck ranges give the methods to weigh heavy automobiles and their tons, making certain conformity with laws and maximizing logistics.

Last but not least, checkweighers automatically contrast the weight of items versus pre-programmed restrictions, boosting top quality guarantee in assembly line (Industrial Scales). Each sort of industrial scale serves a distinct function, dealing with the specific needs of sectors such as production, logistics, food handling, and pharmaceuticals

Benefits of Using Industrial Scales

Regularly using industrial scales provides considerable advantages throughout numerous fields. Among the main advantages is improved accuracy in weight measurement, which is essential for maintaining top quality criteria and governing conformity. Exact dimensions avoid expensive mistakes in inventory, production, and shipping administration, eventually causing increased operational performance.

In addition, commercial ranges are created for durability and effectiveness, allowing them to endure rough environments commonly located in manufacturing and warehousing. This resilience makes sure a lengthy life expectancy, lowering the need for constant replacements and upkeep costs.

Furthermore, using industrial scales enhances safety and security and lessens waste. By guaranteeing that products are evaluated precisely, companies can avoid straining lorries, which can bring about penalties and accidents.

Applications Across Numerous Industries

Industrial ranges play a pivotal duty in various fields, including manufacturing, logistics, food processing, and pharmaceuticals. In manufacturing, these ranges are necessary for making sure that raw products are determined properly, consequently keeping item quality and uniformity (Industrial Scales). Accuracy in weight dimension straight impacts manufacturing performance and expense administration

In logistics, industrial scales assist in the exact evaluating of shipments, which is essential for sticking to delivering regulations and maximizing products costs. Precise weight data assists streamline procedures and improves supply chain management.

The food handling market depends heavily on industrial ranges for conformity with health and wellness policies. They are utilized to evaluate active ingredients specifically, ensuring that solutions fulfill both top quality standards and lawful needs. This is necessary not only for consumer security however likewise for maintaining brand honesty.

Pharmaceutical companies use commercial scales to make sure accurate dosages in drug manufacturing, where also the slightest variance can have considerable effects. Compliance with stringent governing requirements makes accurate weight dimension essential in this sector.

## Elements to Take Into Consideration When Choosing Ranges

Picking the right range for details applications requires cautious consideration of numerous elements. The capacity of the scale is vital; it should fit the maximum weight of the products being measured without exceeding its limitations. Additionally, the readability, or smallest increment the scale can accurately display, is essential for precision, particularly in sectors where weight discrepancies can result in significant economic losses or security issues.

Environmental conditions also play a considerable function in range choice. Ranges used in damp or destructive settings may need customized materials to make sure resilience. Mobility might be crucial in particular applications, necessitating battery-operated and light-weight designs.

Final Thought

In verdict, the selection of industrial scales is crucial for making certain accurate weight measurement throughout varied sectors. Thus, investing in high-quality commercial scales is important for organizations aiming see here to preserve high standards and take full advantage of earnings.

Report this page